Injection Molding vs Overmolding Expert Tips for Choosing the Right Technique

When it comes to manufacturing plastic components, two techniques often come into the spotlight: injection molding vs overmolding. While both are widely used in the production of durable and complex parts, each method has its distinct features, advantages, and best-use scenarios. Understanding the differences between the two can significantly influence your product’s performance, cost-effectiveness, and overall success in the market. Manufacturers and engineers alike must be informed when deciding which approach fits their needs.

Choosing between injection molding and overmolding isn’t always straightforward. The decision hinges on several factors, including material compatibility, end-use application, production volume, and budget. This article breaks down both processes in detail and provides expert tips to help you choose the most suitable technique for your project. Let’s dive deep into the comparison of injection molding vs overmolding and explore how to make an informed decision.

Understanding the Basics: Injection Molding and Overmolding Defined

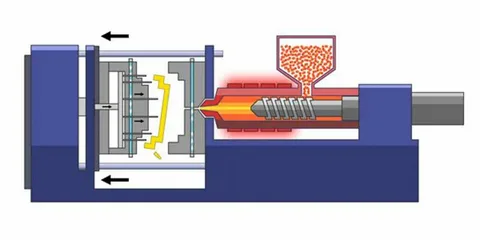

Injection molding is a manufacturing process in which molten plastic is injected into a metal mold cavity, allowed to cool and solidify, and then ejected as a finished part. This process is widely used to create high-volume, high-precision components made from thermoplastics, thermosets, and even some metals. Its popularity stems from its speed, repeatability, and cost-effectiveness in large production runs. Typical applications include everything from automotive parts and consumer electronics to medical devices and packaging components.

Overmolding, on the other hand, is a two-step or two-material injection molding process. It involves molding a base component—often referred to as a substrate—and then molding a second layer of material over it. This second layer can be either the same or a different material and is typically softer or more flexible. Overmolding is often used to add grip, comfort, or functionality to a product, such as rubberized handles on tools or seals on electronic enclosures. In the debate of injection molding vs overmolding, the latter offers enhanced ergonomic and aesthetic benefits but usually comes with higher costs and longer cycle times.

Key Differences: Materials, Complexity, and Functionality

The most notable difference between injection molding vs overmolding lies in the materials used and the complexity of the final product. Injection molding typically involves a single type of material, whereas overmolding requires at least two compatible materials that bond well during the process. These materials must not only adhere physically but also exhibit thermal and chemical compatibility. This makes material selection a crucial step in the overmolding process and adds to the design complexity.

In terms of functionality, overmolding provides distinct advantages for parts that require dual-material functionality or enhanced user interaction. For instance, a toothbrush handle might use a rigid plastic core for structure and a soft rubber exterior for grip. While injection molding is more suitable for simpler, single-material parts, overmolding excels in enhancing functionality, comfort, and visual appeal. Therefore, if your design calls for features like vibration dampening, improved grip, or waterproof sealing, overmolding may be the better choice.

Cost Considerations: Budgeting for Tooling and Production

One of the most critical aspects when comparing injection molding vs overmolding is the cost. Injection molding usually requires a single mold and has lower upfront tooling costs, making it more economical for high-volume production of simple parts. The cost per unit decreases significantly as production volume increases, making it a preferred option for companies looking to scale efficiently. Additionally, the process is highly automated, which further reduces labor costs and cycle times.

Overmolding, in contrast, typically requires two molds or a specially designed mold capable of accommodating multiple materials. This significantly increases tooling costs and setup time. Moreover, the production process is inherently more complex and time-consuming, which can add to the per-unit cost. However, if the added functionality or aesthetic of overmolded parts justifies the investment, the returns can be well worth it. In short, overmolding is ideal when you need enhanced features and are willing to invest in more sophisticated tooling and processes.

Design Flexibility and Application Suitability

When discussing injection molding vs overmolding, another crucial factor to consider is design flexibility. Injection molding is highly versatile and supports complex geometries, but it is typically limited to single-material parts. It offers precision and strength, which makes it ideal for components that require high dimensional accuracy and structural integrity. Applications range from automotive dashboards and surgical instruments to toy parts and bottle caps.

Overmolding, while more limited in terms of compatible material pairings, excels in design flexibility related to tactile feel, branding, and multi-functionality. For example, adding a soft-touch surface or integrating multiple textures into a single product is feasible only with overmolding. It is particularly useful in consumer products, medical devices, and electronics where the user experience is a priority. In summary, if your product requires a more interactive or ergonomic interface, overmolding may be the better route to take.

Expert Tips for Choosing the Right Technique

Experts recommend evaluating the end-use application before deciding between injection molding vs overmolding. If your product’s performance relies on a single, strong, and precisely shaped component, then injection molding is likely the more appropriate choice. It is ideal for products that require structural support, uniformity, and high production volumes. Always consider the mechanical properties and environmental conditions the part will be exposed to, as these factors heavily influence the material and process choice.

For projects that demand a multi-material solution or enhanced user interaction, overmolding is the preferred technique. However, it is essential to consult with materials engineers early in the design phase to ensure compatibility and proper bonding between the substrate and the overmold material. Also, ensure that your production volumes justify the higher initial investment. Lastly, prototyping can be a valuable step to test both approaches on a smaller scale before committing to full-scale production.

Conclusion

In the comparison of injection molding vs overmolding, there is no one-size-fits-all answer. The decision depends heavily on your specific application, budget, design requirements, and long-term product goals. Injection molding offers speed, repeatability, and cost-effectiveness for single-material parts. It’s the go-to choice for high-volume production where durability and precision are key.

Overmolding, on the other hand, provides added value in terms of functionality, aesthetics, and comfort. It’s particularly useful when a product demands more than just structural strength—such as enhanced grip, shock absorption, or water resistance. Understanding the core differences and aligning them with your project requirements will help you choose the right technique, saving both time and money in the long run.

We are excited to announce the **launch of the Sharkbow Marketplace!** 🎉 Now you can:

- 🛍️ List and sell your products – Open your own store easily.

- 📦 Manage orders effortlessly – Track sales and communicate with buyers.

- 🚀 Reach thousands of buyers – Expand your business with ease.

Start selling today and grow your online business on Sharkbow! 🛒

Open Your Store 🚀 ✖🚀 What Can You Do on Sharkbow?

Sharkbow.com gives you endless possibilities! Explore these powerful features and start creating today:

- 📝 Create Posts – Share your thoughts with the world.

- 🎬 Create Reels – Short videos that capture big moments.

- 📺 Create Watch Videos – Upload long-form content for your audience.

- 📝 Write Blogs – Share stories, insights, and experiences.

- 🛍️ Sell Products – Launch and manage your online store.

- 📣 Create Pages – Build your brand, business, or project.

- 🎉 Create Events – Plan and promote your upcoming events.

- 👥 Create Groups – Connect and build communities.

- ⏳ Create Stories – Share 24-hour disappearing updates.

Join Sharkbow today and make the most out of these features! 🚀

Start Creating Now 🚀- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness